- THE COMBINATION OF PAINTING AND PRINTING

|

|

|

|

|

Metallic TrendColor + PorColor + Polylux |

Glossy TrendColor + Polylux imprint (CMYK) |

TrendColor +SoftTouch + Polylux imprint (CMYK) |

Glossy TrendColor + Polylux |

• DEEP EFFECT

|

|

|

|

|

Deep Effect on white Porcelain |

Glossy TrendColor + Deep Effect |

Glossy TrendColor + Deep Effect |

Glossy TrendColor + Deep Effect |

• Examples of additional printing positions

|

|

|

|

|

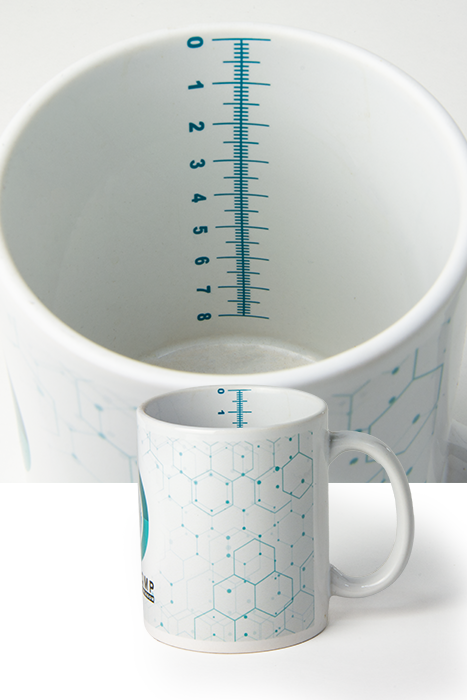

Inside print Transfer Plus + TrendColor + Deep Effect |

Imprint print Polylux + Digital Print |

Inside print Transfer Plus + TrendColor transparent |

Bottom outside imprint |